What is CNC Turning?

Are you thinking about different manufacturing methods to make your part(s)? Want to learn more about CNC turning to determine if it’s suitable for your application?

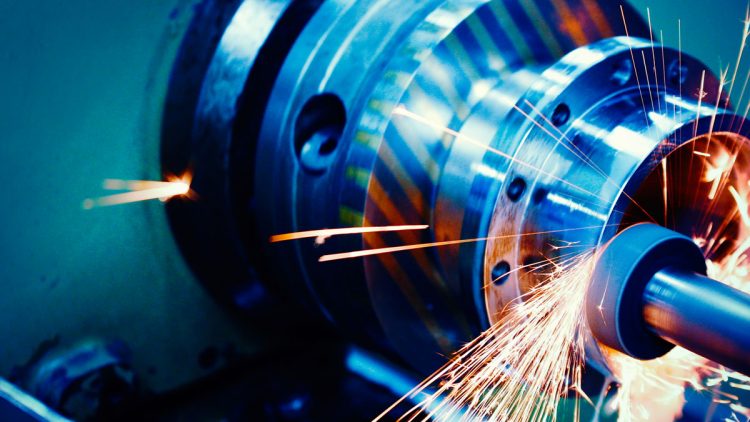

CNC Turning is a method of manufacturing in which bars of material are kept in a chuck and “turned” while a device is fed to the piece for removing material to create the required shape. A turret, with a device attached is programmed for moving the bar of raw material and eliminates material to create the pre-programmed result. This is also known as “subtraction machining” due to it involving material “subtraction”. If the machine shop has both tuning and milling abilities the rotation can be stopped for allowing the milling out of additional shapes.

Meaning of CNC Turning

CNC Turning can be broke down into 2 parts:

- “CNC” is an acronym for computer numerical control and portrays the mechanization of a machining method.

- “Turning” is a method in which the workpiece turns whereas a single pointed cutting device removes material.

The initial material, though usually round, can be other shapes like hexagonal or squares-shaped raw materials.

Subject to the bar feeder, the length of the bar can differ. This impacts how much handling is needed for high-volume jobs.

CNC lathes or CNC turning machine shops have tools installed on a turret in which is controlled via computer. The more tools that the turret can accommodate, the more choices are available for intricacies on the part.

CNCs with “live” tooling choices, can stop the bar rotation and add additional features like drilled holes, slotted and/or milled areas.

Many CNC turning shops have a single spindle, allowing work to be done all from one side, whereas other turning shops, have two spindles, a primary and sub-spindle. A part can be partially machined on the primary spindle, moved to the sub-spindle and have added work done to the other side of this configuration.

CNC Turning

There are many various kinds of CNC turning shops with different types of tooling and spindle options, outer diameter restrictions in addition to speed and power capacities that impact the types of parts that can be inexpensively made on it.

Turning is an adaptable machining method capable of making a wide variety of profiles subject to the turning method used. The usefulness of lathes and turning shops allows for straight turning, knurling, taper turning, external grooving, boring, threading, and drilling.

Overall, lathes are limited to more simple turning operations, such as straight turning, external grooving, threading, and boring processes. The tool turret on turning shops allows the shop to finish all the operations of a lathe in addition to more complex operations, like drilling off the rotation axis.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Turning in the Chandler, Arizona and surrounding areas. When you need precision CNC turningand milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.