What Is CNC Machining?

CNC stands for Computer Numerical Control. This completely automated motion control machine has three components, including a motion system, command function and feedback system. CNC machining is simply the process of using a computer-operated machine to produce parts of a solid material into a desired shape. Read on for more information on how CNC machines are used today.

What Can A CNC Machine Do?

The goal of the CNC machine is to make precise cuts into pieces of metal for industrial uses. Additionally, the systems inside the CNC include:

- Wood routing

- Turret Punching

- Wire-Bending Abilities

- Foam Cutting

- Laser Etching and Cutting

- Cylindrical Grinding

- 3D Printing

- Glass Cutting

- Embroidery Machines

CNC machines can efficiently perform intricate cuts in a matter of minutes. However, it is dependent on how your CNC machine is programmed to function and act within the specified code. The machine only operates according to the instructions given to it by the program within the system. The CNC machine should have the code programmed inside, ready to start designing products. The final result will emerge once the program and shaping process has been completed.

CNC Machine Types

Original numerical control machines date all the way back to the 1940s. Back then, using a motor was essential for other devices’ movement. While technology advanced, this helped the CNC machine lead the industry in a different direction earlier than expected. CNC machines were originally controlled by analog computers, and later, digital computers.

There is a whole line of CNC machines that are entirely electronic. Most commonly CNC’s include some form of ultrasonic welding, laser etching, and hole crafting. Here is a list of the more common CNC machines being used today:

CNC Mill

CNC milling is a machining method that utilizes computerized controls and spinning multi-point cutting devices to remove material from a workpiece. The end result will be custom-designed parts or products.

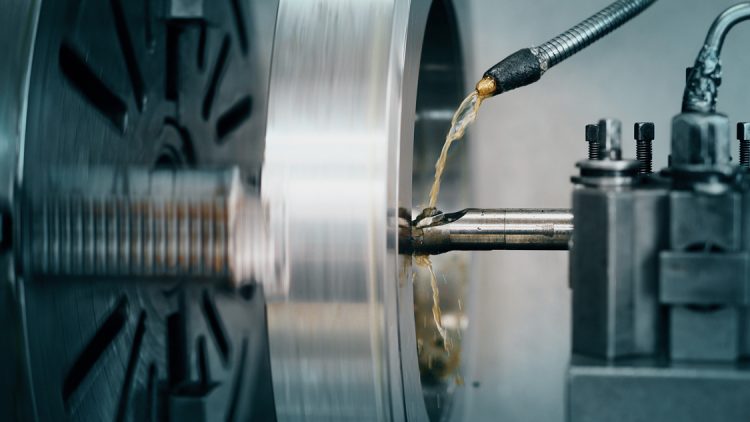

Lathes

This particular machine rotates a piece through an axis of rotation (x and y respectively) to perform various processes. These tasks include cutting, knurling, sanding, drilling, deformations and turning.

Plasma Etching/Cutting

Plasma Etching is the elimination of silicon, plastic, or other non-metallic materials using plasma which is produced by exciting ions in a gas; typically oxygen and CF4. Those ions crash into the material at an atomic level and remove it without needing chemical acids.

Electric Discharging Machine (EDM)

Electrical discharge machines (EDM) use a nontraditional technique where material is removed from a workpiece via thermal energy. A lot like processes such as laser cutting, EDM doesn’t require mechanical pressure in the removal process.

There Are Two Different Sub Types Of EDM’s:

- In wire electrical discharge machines, a slim single-strand metal wire, is slipped across the piece. This wire will be submerged in a bath of dielectric fluid, generally deionized water.

- Electrical Discharge Machine or sinker EDM machining processes an electrically charged electrode calibrated to a particular configuration to burn the configuration of the electrode into a metal element. This type of process is usually used to produce molds and dies.

Water Jet Cutters

A waterjet cutter uses high-pressure streams of water to eat away at a slender line in the piecework. Used for cutting a wide range of material, including tool steel and titanium to foam, a granular abrasive is implemented to the waterjet. This will increase the jet’s cutting power. Since the abrasive is implemented at the nozzle, it is easy to change between just water and abrasive waterjet cutting.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.