CNC Milling Cost

A CNC milling machine will cost $60,000 on average, according to ManufacturingTomorrow. If a personal machine is too expensive, what can you expect to pay for a professional CNC milling project? This post will look at all the factors influencing overall cost.

What Is CNC Milling?

Milling is the process of drilling and cutting materials, such as metal or wood. A milling machine will utilize a tool called a milling cutter to perform its duty, regardless of whether it is operated through CNC or manually. This tool is held in a spindle and can vary in size, depending on the project’s needs.

The CNC milling machine’s ability to cut in different angles and move along different axes is what separates it from other drilling machines. To account for the various angles and axes, there are a few different milling machines, including:

- 2-axis milling machines.

- 3-axis milling machines.

- 4-axis milling machines.

- 5-axis milling machines.

- CNC milling machines (2-5 axis).

CNC Milling Cost Factors

Several different factors will contribute to the overall cost of the CNC milling process. These six things will impact the bottom line: tools, materials, machining, quality tests, technician and shipping.

Tools

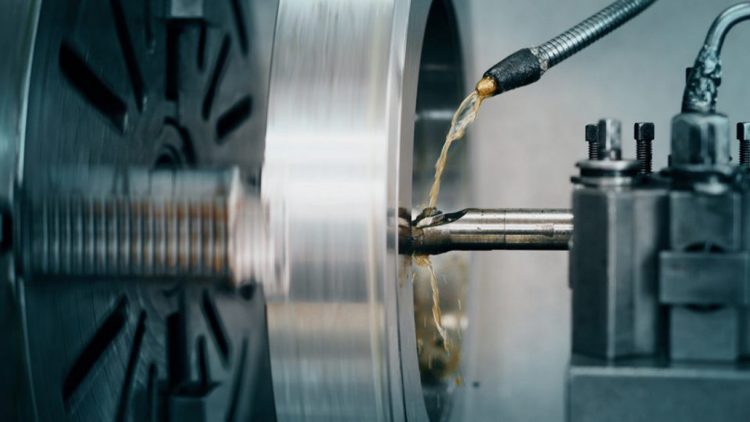

If a handyman mentions tooling, this means he is charging you for the tools he needs for the job. Necessary tools for CNC milling include fixtures, tool holders, jigs and loading mechanisms, among others. Each of these costs cannot be automatically estimated. Most CNC milling shops do operate at 95% efficiency, though. Milling requires using both cooling liquids and tools. Both elements will eventually need to be replaced over time. Cutting tools will not last as long as liquids since they are responsible for cutting dense materials.

Materials

Every milling process will begin with a manufacturing project. So, to get the project started, money will be spent on the necessary materials. Milling is all about geometry and shape. You need the material to be one of two forms: plate or sheets, and as cubes.

Machining

As expected, milling will use a lot of electricity. 5-axis CNC milling machines use a ton of power, for example. Most devices are already set in place with pneumatic systems used to enhance performance. This additional system will only use up more energy. Fees will only increase if finished parts have to be processed on multiple machines.

Quality Tests

Each and every milled part has different quality requirements. Precise and polished finishes will come with higher costs. Milling manufacturing operations account for the number of faulty products based on a given rate to the customer.

Technician

Milling jobs will require a set of hands to achieve the best results possible. Utilizing a trained professional will always cost money. Costs will go up based on how much care the job/material needs.

Shipping

Yes, there are a lot of shipping options nowadays, but most milling companies have pre-existing partnerships to handle logistics. So, the worry of shipping will be taken out of the customer’s hands, but it can be costly.

CNC Milling Services

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP, located in Chandler, Arizona, specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.