What Is CNC Milling?

If you are searching for “what is cnc milling“, East Valley Precision is here to help!

What Is A CNC Machine?

CNC stands for Computer Numerical Control. This completely automated motion control machine has three components, including a motion system, command function and feedback system. CNC machining is simply the process of using a computer-operated machine to produce parts of a solid material into a desired shape.

What Is A CNC Milling Machine?

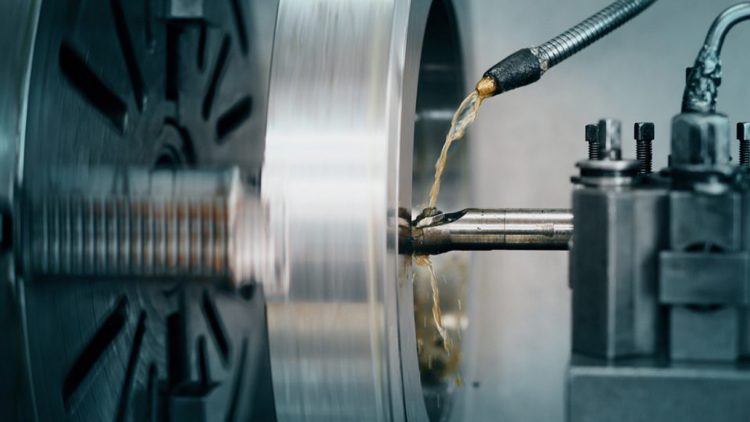

Milling is the process of drilling and cutting materials, such as metal or wood. A milling machine will utilize a tool called a milling cutter to perform its duty, regardless of whether it is operated through CNC or manually. This tool is held in a spindle and can vary in size, depending on the project’s needs.

The CNC milling machine’s ability to cut in different angles and move along different axes is what separates it from other drilling machines. To account for the various angles and axes, there are a few different milling machines, including:

- 2-axis milling machines.

- 3-axis milling machines.

- 4-axis milling machines.

- 5-axis milling machines.

- CNC milling machines (2-5 axis).

CNC Milling Machine Types

Despite the axis classifications, there are other ways to define the milling machine types. For example, a vertical mill will feature 3-axis with a table, arm and attached spindle. Both the table and arm will be connected to a vertical column with this model of machine. The table will then move up and down along the z-axis, meeting the arm.

With a turret vertical mill version, the spindle will be stationary and the table will move along both the x and y-axis. A bed vertical mill, meanwhile, can only move along the x-axis. A horizontal mill is nearly the same as the vertical mill, yet only differs with the spindle oriented horizontally. A knee mill features an adjustable knee, enabling columns to move up and down.

CNC Milling Tool Types

Each different milling machine will utilize a variety of specialized tools. Some larger machines can even change tools during a cut. If you choose an overly strong steel tool for a wood cut, you could end up with a damaged product. Wood tools used for steel cuts can end up breaking the tool, altogether. A milling cutter is the most basic tool. Cutters will vary in shape and size for precise cuts.

What Can A CNC Milling Machine Do?

The goal of the CNC milling machine is to make precise cuts into pieces of metal and metal for industrial uses. Additionally, these systems can be used for the following:

- Woodworking.

- Furniture.

- Instruments.

- Cabinets.

- Aluminum.

- Signs.

- Sculptures.

CNC machines can efficiently cut the following materials:

- Steel.

- Titanium.

- Copper.

- Zinc.

- PVC.

- Plywood.

- Stone.

CNC Milling Services

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP, located in Chandler, Arizona, specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.