How To Use A CNC Machine

CNC machines are automated motion control machines that consist of three components: a motion system, feedback system and a command function. The goal of CNC (Computer Numerical Control) is to make precise cuts of metal pieces for industrial use. So, how do you operate these machines? Let’s take a look!

Materials Needed

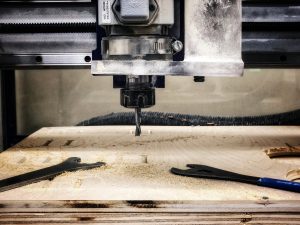

The first step toward using a CNC machine is figuring out what you want to use it for. Are the materials soft, such as plastic or wood, or are you working with metal? The type of material you are using will dictate the type of machine needed. If you are working with wood, then a CNC router should be used, while a CNC milling machine is necessary for any metal projects.

CNC Software

Every CNC machine uses computer software to control their movements. The software entails a three-step process. Parts are drawn in a CAD program (computer-aided design), then a CAM program (computer-aided manufacturing) will convert the drawing into a code called g-code. The machine will then read the g-code and complete the formation of the part. Some machinists will write the g-code directly into the machine, but most individuals still rely on CAM programs.

CAD Programs

CAD programs are available to buy from the majority of software shops, with other free versions found online. It’s a good idea to try free programs before investing in more advanced packages. Use the CAD program gridlines when drawing to be specific about your measurements.

CAM Programs

After you have completed the drawing, import the file into a CAM program. At this point, things become more complex since you have to tell the software what types of tools to use and how deep the cuts need to be. Once you have defined the tools, it’s time to create a g-code for the machine to read. The g-code will be automatically created once you have finished inputting the information.

G-Code

Commercial CNC machines will transfer the g-code directly to the machine, while smaller ones are typically run by external PCs. These should have a machine control program that uploads the g-code to the program, starting the final process. If you wish to type the g-code directly into the machine, then find the g-code reference for the machine. You can type the command straight into the program, bypassing both the CAD and CAM processes.

CNC Machine Types

There is a whole line of CNC machines that are entirely electronic. Most commonly, CNC’s include some form of ultrasonic welding, laser etching, and hole crafting. Here is a list of the more common CNC machines being used today:

CNC Milling

CNC milling is a machining method that utilizes computerized controls and spinning multi-point cutting devices to remove material from a workpiece. This process will rapidly cut solid metal and plastics into smaller and final parts. Smooth finishes are possible, as well as producing 2D or 3D shapes. CNC milling machines can create parts for mechanisms, engines, enclosures and more. The end result will be custom-designed parts or products.

CNC Lathes

This particular machine rotates a piece through an axis of rotation (x and y respectively) to perform various processes. These tasks include cutting, knurling, sanding, drilling, deformations and turning. A CNC lathe is used to cut away any excess materials by rotating a piece on a spindle. Different drilling bills and cutters will chip away at the material(s). CNC lathes can be configured to cut precisely and efficiently. Such precise cuts would not be possible if done manually.

CNC Plasma Cutter

Plasma Etching is the elimination of silicon, plastic, or other non-metallic materials using plasma which is produced by exciting ions in a gas; typically oxygen and CF4. Those ions crash into the material at an atomic level and remove it without needing chemical acids. Within CNC plasma cutters, gas will be blown from a nozzle to the surface at very high speeds. Gas is then converted into plasma, with a temperature up to 50,000 degrees.

CNC Laser Cutter

CNC laser cutters are very similar to CNC plasma cutting machines. The biggest difference between the two, of course, is the use of the laser for cutting purposes. Lasers are tremendous tools used to cut metals, hardwoods and plastic materials. The intensity of the laser can be adjusted depending on the strength and density of the materials that needs to be cut.

Electric Discharging Machine (EDM)

Electrical discharge machines (EDM) use a nontraditional technique where material is removed from a workpiece via thermal energy. A lot like processes such as laser cutting, EDM doesn’t require mechanical pressure in the removal process.

The Two Different Sub Types Of EDM’s:

- In wire electrical discharge machines, a slim single-strand metal wire, is slipped across the piece. This wire will be submerged in a bath of dielectric fluid, generally deionized water.

- Electrical Discharge Machine or sinker EDM machining processes an electrically charged electrode calibrated to a particular configuration to burn the configuration of the electrode into a metal element. This type of process is usually used to produce molds and dies.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.