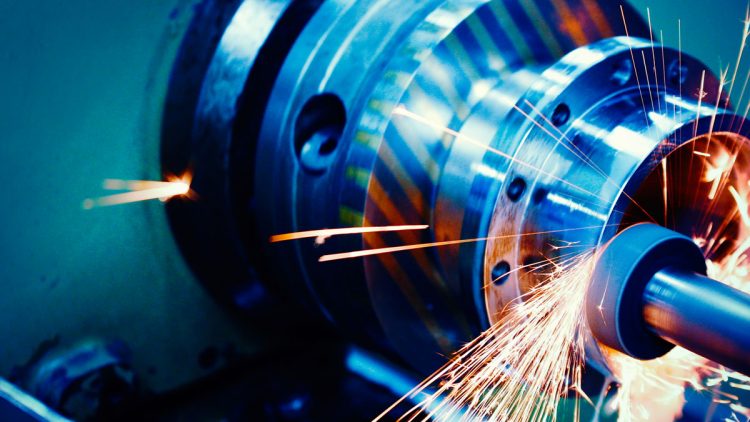

Machining vs Milling

Overall, machining is an umbrella term covering various techniques used for shaping materials, usually metals and plastics, by removing unnecessary material. It includes processes such as turning, grinding, drilling, and particularly milling. On the other Hand, milling is a machining process that utilizes rotary cutters for removing material from a work piece at an angle to the machine’s axis. This post is going to explain the variations between machining and milling and share information regarding their features, and applications.

Understanding Machining

Machining is a manufacturing process that entails removing material from material to achieve a desired shape. It is a reductive process, which means it cuts away material to form the final piece. The common types of machining processes are as follows:

Turning: Involves rotating the material while a cutting tool moves linearly for removing material. It is generally used for producing cylindrical parts.

Drilling: Uses a spinning drill-bit for creating round holes in a work piece, making holes for fasteners or other pieces.

Grinding: Utilizes an abrasive wheel for removing material and attain a high surface finish or close tolerances, usually used for finishing processes.

Milling: Utilizes rotary cutters for removing material, allowing for a broad range of shapes and intricate geometries. Basically, milling rotates the cutters, not the other way around, in comparison to turning. Machining is crucial in manufacturing as it creates high-precision components with close tolerances and outstanding surface finishes. Apart from its application in bulk production, CNC (Computer Numerical Control) machining is widely used in quick prototyping and reduced-volume production for customized parts.

Understanding Milling

Milling is a distinct type of machining technique that involves utilizing rotary cutters for removing material from a work piece. Milling varies from other machining processes as its tool moves along with the work piece. Allowing the creation of intricate curves, shapes, and surfaces. Milling can work on a lot of materials, such as metals, plastics, and aggregate, which makes it adaptable in many sectors. It has a lot of different operations, like end milling, face milling, and grooving. Eli Whitney first invented the milling machine in the early 1800’s, the start of milling history. This machine was designed for producing exchangeable parts for firearms. It altered manufacturing by making it more accurate and efficient. Eventually, milling technology has evolved considerably, with progression in CNC technology in the late 20th century, therefore turning milling into a highly automated and accurate process. CNC milling machines can make complex parts with little to no human intervention, increasing productivity and regularity. Key Differences Between Machining and Milling Machining and milling are both vital in the manufacturing process, nonetheless, they differ considerably in scope, how they operate, equipment, and material removal methods.

Applications for Machining and Milling

Machining and milling are vital in various sectors because of their ability to produce accurate and intricate components. Sectors that rely heavily on these processes include aerospace, electronics, automotive, medical devices, and manufacturing, to name a few.

- Aerospace: In aerospace industries, machining is vital for producing highly accurate components like turbine blades, parts for engines, and structural parts. Milling is specifically used for creating intricate geometries and detailed characteristics required for aerodynamics and performance.

- Electronics: In electronics, machining is utilized to manufacture housings, heat sinks and connectors. Milling is usually applied for creating intricate enclosures that require accurate dimensions and high surface polishes.

- Automotive: The automotive industry utilizes machining to manufacture engine blocks, transmission parts, and intricate components such as shafts and gears. Plastic parts and automotive body panels are shaped utilize milling methods.

- Medical Devices: The medical sector depends on machining to create surgical instruments, prosthetics, and implants. Milling is necessary for crafting intricate shapes required in custom implants and dental tools.

- Manufacturing: General manufacturing utilizes machining for dies and tool making, creating jigs, prototypes, and fixtures. Milling is helpful for creating dies and molds with intricate contours and cavities.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.