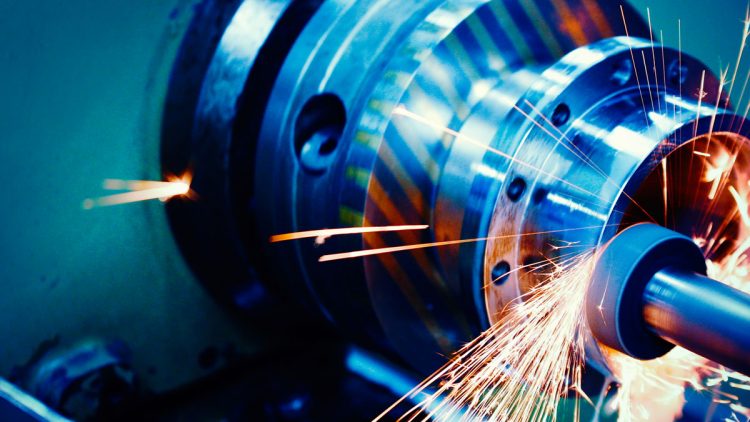

Different Lathe Types

CNC machining centres may come with live tooling. While single-point cutting tools are suitable for most turning operations, live tooling refers to mills, drills and other tools that have their own power. This allows the creation of keyways or holes perpendicular to the part axis without using any other machinery in the process.

Control panel

This is where computer numerical control kicks in. The brains of CNC turning machines are just behind the panel. The panel itself allows the operator to adjust the program and start it.

Types of Lathes

A wide range of CNC lathes offers a variety of possibilities. Each comes with a unique set of features while some are more automated than others. So everything has its place, whether a few one-off jobs at a small machine shop or batch production for larger quantities.

Bench lathe

The name suggests that it is small enough to attach it to a tailored workbench. They are, still, larger than micro or mini-lathes.

A great way to perform general machining or a special tool for a hobbyist, it can perform many of the necessary operations. A bench lathe requires a skilful machinist as there is little to no automation, putting more responsibility on the operator.

Engine lathe

The most common type of lathe. The name has stuck since the 19th century when a steam engine made this specimen stand out in the midst of other manual lathes. Since the beginning of the 20th century, a conversion towards electric motors got on its way.

Using gearboxes in the headstock made the choice of spindle speed easy and high-speed machine tools became the norm. The new-found power pushed the industry to invent new ways of increasing the tool life. Replaceable carbide inserts were just the way to do that.

As a result, engine lathes can perform CNC machining at high speeds, leading to shortened production times and lower costs. Although still common in workshops, engine lathes laid the foundation for improved performance and the automation of machining.

Toolroom lathe

Similar to an engine lathe with a few differences. Usually, they are smaller in size to fit in tighter spaces. At the same time, there are some extra capabilities available, making it rather a higher-end machine, not one suitable for entry-level.

The toolroom lathes include chuck and collets, taper attachment among other things that, for example, simpler bench lathes do not have.

Turret and capstan lathes

These types of lathes are pretty much interchangeable based on the operations they can perform. As you learned before, the use of a turret opens up a wide range of automation possibilities. Also, many more operations can be performed on a single workbench.

From turning and boring to drilling, threading, and making keyways, everything is possible without a change of tools. The turret holds all the necessary tooling at once, so you can easily go from one process to the next.

Coupling CNC with fewer manual tasks, and producing almost identical machined parts in batches is a strong point of this type of lathe.

Swiss-type lathe

Swiss lathes operate with incredibly small tolerances at shorter cycle times than conventional lathes, making them an attractive option for manufacturing complex parts at larger volumes.

Swiss machines have a moving headstock, allowing the workpiece to be repositioned along the z-axis as it undergoes the machining process. In other words, to cut lengthwise along the part, the tools will move in and the material itself will move back and forth along the z-axis. This allows all the work to be done on the material near the guide bushing where it is more rigid, eliminating deflection and vibration.

Multispindle lathe

The multispindle lathe has more than a single spindle. The additional capacity is especially suitable for high-volume production.

Setting up the machine requires quite a lot of time, so the combination of this and the high cost of the machine itself needs high-volume production to pay it off. When applying this, they can create similar parts with high precision, low cycle times and very little manual work aside from the initial setup.

So large-batch manufacturing can considerably lower the cost of CNC machining.

CNC lathe

Although some of the aforementioned types also accommodate a CNC system, the CNC lathe deserves a separate mention.

CNC refers to computer numerical control, which takes care of operating the machine to some extent. This depends on the specific machinery, as they can be fully or semi-automatic.

Semi-automatic CNC lathes need a little more work from the machine operator whereas fully automatic centres are able to do everything from mounting the workpieces to changing the tools.

The highly accurate CNC machines are the best the contemporary industry has to offer. Digitising the whole process from the creation of CAD to a fully finished part is possible. Also, the enclosures significantly reduce the risk during machining, as the workers are not really exposed to any moving components, controlling anything necessary from a computer screen.

East Valley Precision – Custom Machinery Specialists

East Valley Precision offers custom CNC Turning in the Chandler, Arizona and surrounding areas. When you need precision CNC turning and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.