CNC Machine Pricing 2025

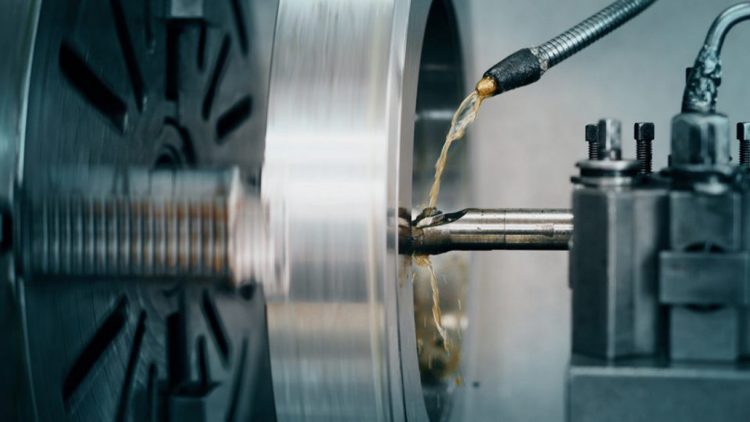

Cutting, drilling, and milling can be automated with the use of a CNC (Computer Numerical Control) machine. It is controlled by a computer program that provides precise instructions to the machine. As a result, it is significantly faster and more accurate than performing the same task by hand.

Five Elements That Affect CNC Machine Costs:

1. Machine Type:

CNC machines perform a variety of tasks, such as metalworking, shaping, and cutting. The price depends on the type you require. For instance, metalworking equipment is frequently more expensive. To prevent overspending, specify exactly what you want the machine to do.

2. Dimensions and Capacity:

The price is affected by the machine’s size and capabilities. Larger workpieces require larger machines, which are more expensive. Cutting capability and precision are also important and can raise the machine’s cost. When choosing a machine, consider your needs and financial situation.

3. Quality & Brand:

The manufacturer’s quality and brand are important. Although well-known brands may be more expensive, they typically last longer and offer better support. To determine whether the product is worth the cost, look at the manufacturer’s track record.

4. Technology & Features:

More features, such as automated tool changers and sophisticated control systems, are now available for CNC machines. The machine costs more because of these extras. Think about the features you actually need for your job and whether the higher cost is justified. A machine’s price increases with its features and technology.

5. Personalization:

Certain CNC machines can be tailored to meet specific requirements. However, this may raise the overall cost. Consider whether customization is truly necessary for your work and whether the increased cost is justified.

CNC machine prices in 2025:

We now know what influences the price of CNC machines. Let’s examine the typical prices of various CNC machines in 2025.

CNC Milling Equipment:

Small to medium-sized businesses can benefit from entry-level CNC milling machines, which range in price from $10,000 to $30,000.

Mid-range CNC milling machines: These machines have greater precision and capabilities and range in price from $30,000 to $100,000.

High-end CNC milling machines: These sophisticated devices, which can cost anywhere from $100,000 to $500,000, offer state-of-the-art technology and high productivity for manufacturing on a large scale.

CNC Lathe Devices:

Entry-level CNC lathes are perfect for simple turning tasks and typically range in price from $10,000 to $30,000.

CNC lathe machines in the middle range: These options, which range in price from $30,000 to $100,000, provide greater versatility for intricate turning tasks.

High-end CNC lathe machines: These are extremely accurate and versatile machines that range in price from $100,000 to $500,000.

CNC Router Devices:

CNC routers at the entry level: They range in price from $5,000 to $20,000 and are suitable for hobbyists and small enterprises.

Mid-range CNC routers: These machines have additional features for larger projects and range in price from $20,000 to $75,000.

High-end CNC routers: With state-of-the-art features for industrial use, these sophisticated routers can range in price from $75,000 to $200,000.

CNC Plasma Cutting Devices:

Entry-level CNC plasma cutting machines are ideal for small to medium-sized metal fabrication companies and are typically priced between $10,000 and $30,000.

Mid-range CNC plasma cutting machines: These machines, which range in price from $30,000 to $100,000, provide better cutting capabilities and precision.

High-end CNC plasma cutting machines: Costing between $100,000 and $500,000, these machines offer remarkable accuracy for difficult metal cutting jobs.

CNC Laser Cutting Devices:

Entry-level CNC laser cutting machines: These machines, which range in price from $20,000 to $50,000, are good at precisely cutting materials like wood, plastic, and metal.

CNC laser cutting machines in the middle range: These range in price from $50,000 to $200,000 and provide sophisticated laser cutting capabilities and versatility.

High-end CNC laser cutting machines: Due to their ability to cut a wide range of materials with extreme precision and complexity, these machines can cost $200,000 or more.

Five Clever Pointers for Purchasing CNC Machines:

Use these helpful pointers to help you choose a CNC machine wisely:

1. Recognize Your Needs:

Determine what your CNC machine is capable of first. Is it for tasks like cutting or shaping? Additionally, think about the materials you’ll be using and the size of your workpieces.

2. Create a Budget:

Create a budget that is reasonable for your needs and financial circumstances. Keep in mind that more basic machines can frequently perform tasks just as well as more sophisticated ones.

3. Pick a Reputable Company:

Seek out reputable businesses with a track record of producing dependable machinery. Although they might be more expensive, you’ll probably receive better assistance.

4. Examine the Market for Used Machines:

Don’t discount used CNC equipment. If they’re in good shape, they might be a more affordable choice. To prevent future issues, make sure to thoroughly inspect and test the used machine before purchasing.

5. Finance Options

Examine leasing or financing options provided by financial institutions or manufacturers. You can spread out the CNC machine’s cost over time with the aid of these plans. Flexible payment plans are even provided by certain manufacturers, which is particularly advantageous for companies with tight budgets.

CNC Milling Services By East Valley Precision

Equipped with over 40 years of experience, East Valley Precision has been offering top-notch customer service and machinery work throughout the valley. EVP, located in Chandler, Arizona, specializes in CNC milling, turning, surface grinding, engineering and water jet cutting. This company also has extensive experience in machining aluminum, stainless steel, titanium and plastics. With customers from the medical, semiconductor and pharmaceutical industries, you can rest assured that any of your needs can be taken care of by EVP.

East Valley Precision offers custom CNC Machining in the Chandler, Arizona and surrounding areas. When you need precision CNC machining and milling contact East Valley Precision. Call us at 480-288-6601 for more information or use our form for a quote.